Īmerican industrialists recognized the threat of cheap offshore labor to American workers during the 1910s, and explicitly stated the goal of what is now called lean manufacturing as a countermeasure. In this way, inventory levels were kept low, investment in in-process inventories was at a minimum, and the investment in purchased natural resources was quickly turned around so that additional materials were purchased." Plenert goes on to explain Toyota's key role in developing this lean or just-in-time production methodology. in which the only materials housed in the factory were those on which work was currently being done. Thus, the Japanese "leaned out" their processes. Japan had high unemployment, which meant that labor efficiency methods were not an obvious pathway to industrial success.The Japanese islands lack natural resources with which to build products.

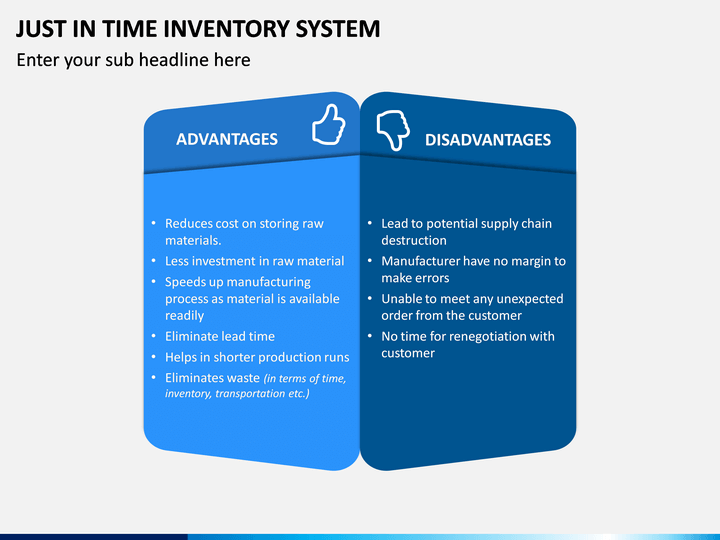

It may also impact negatively on workers due to added stress and inflexible conditions. The downside is that it requires producers to forecast demand accurately as the benefits can be nullified by minor delays in the supply chain.

By receiving goods only as they need them for the production process, it reduces inventory costs and wastage, and increases productivity and profit. The term Lean was coined in 1988 by American businessman John Krafcik in his article "Triumph of the Lean Production System", and defined in 1996 by American researchers James Womack and Daniel Jones to consist of five key principles: "Precisely specify value by specific product, identify the value stream for each product, make value flow without interruptions, let customer pull value from the producer, and pursue perfection." Ĭompanies employ the strategy to increase efficiency. The seven "wastes" ( muda in Japanese), first formulated by Toyota engineer Shigeo Shingo, are the waste of superfluous inventory of raw material and finished goods, the waste of overproduction (producing more than what is needed now), the waste of over-processing (processing or making parts beyond the standard expected by customer), the waste of transportation (unnecessary movement of people and goods inside the system), the waste of excess motion (mechanizing or automating before improving the method), the waste of waiting (inactive working periods due to job queues), and the waste of making defective products (reworking to fix avoidable defects in products and processes). Toyota's system was erected on the two pillars of just-in-time inventory management and automated quality control. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japanese automobile company Toyota called " The Toyota Way" or the Toyota Production System (TPS). Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers.

0 kommentar(er)

0 kommentar(er)